Solway, a well-known brand in the solar lighting industry, has extensively used its products in rural road lighting projects. The following is a comprehensive, representative virtual construction case study, showcasing the entire project process from project background to completion and acceptance.

Project Name: "Beautiful Countryside" Lighting Project in a Certain Province and City - Xinshengyang Solar Streetlight Installation Project

I. Project Background and Requirements Analysis

Project Location: Main roads and lanes in a certain village.

Original Situation: Village roads were unlit at night, or had only a few old, dimly lit streetlights. This made nighttime travel inconvenient for villagers, posed a safety hazard, and affected the overall appearance of the village and nighttime activities.

Core Requirements:

Safe Travel: Provide villagers with adequate lighting for nighttime travel.

Energy Saving and Environmental Protection: In line with national green and low-carbon policies, the system utilizes clean solar energy, resulting in zero electricity costs and eliminating the need for complex cabling.

Intelligent and Convenient: Requires light control and timed automatic switching, eliminating manual operation and enabling intelligent management.

Economical and Durable: Simple construction, low maintenance costs, and a long service life.

II. Solway Solar Street Light Solution and Product Selection

After a field investigation and light analysis, the Solway technical team customized the following solution for the client:

Selected Model: Solway's SW-Matrix Series Single-Arm Two-in-One Solar Street Light

Product Highlights:

Light Source: 120 high-quality 2835 LEDs, offering high luminous efficiency, excellent color rendering, and a lifespan of up to 50,000 hours. Brightness is equivalent to that of a traditional 60W-80W sodium lamp, with an actual power draw of 30W-40W (adjustable).

Solar Panel: Monocrystalline silicon solar panel with a conversion efficiency of >21% and a power draw of 60W-80W, ensuring efficient charging even on rainy days.

Battery: Built-in high-performance ternary lithium battery (or lithium iron phosphate battery) with a capacity of 12,000mAh-20,000mAh, ensuring continuous lighting for 3-5 days on rainy days.

Smart Controller: Solway's patented MPPT smart controller improves charging efficiency by 30%. It features both light control and timer control (automatically turns on at night and automatically reduces power to save energy after a set timer), as well as optional motion detection and radar detection (full illumination when people or vehicles pass by, dimmed afterward).

Light poles: Made of high-quality Q235 steel, hot-dip galvanized for corrosion protection and then spray-coated with plastic. They are 6 meters tall, have a wind resistance rating of ≥10, and are designed to last over 15 years.

III. Detailed Construction and Installation Process

Phase 1: Preliminary Preparation and Survey (1-2 days)

Site Survey: Technicians and the construction team will measure the length and width of the road to determine the optimal streetlight layout. In this example, the main road is 5 meters wide, so a double-sided staggered layout is used with poles spaced 25-30 meters apart. The laneway is 3 meters wide, so a single-sided layout is used with poles spaced 20-25 meters apart.

Stakeout: Based on the design drawings, lime powder or markers are used to determine the exact location of each streetlight base, avoiding underground pipelines.

Material Preparation: Xinshengyang streetlight components, embedded parts (ground cages), cement, sand, and other materials were transported to the site.

Phase 2: Foundation Construction (2-3 days)

Excavation: A standard-sized foundation pit (typically 60cm x 60cm x 70cm deep) was excavated using an excavator or by hand.

Pour Foundation: The embedded parts (ground cages) were placed, ensuring they were level and the bolts were at consistent heights. Then, the foundation was filled with C25 or C30 concrete. This is crucial for ensuring the stability of the light pole.

Curing: The concrete foundation requires a curing period of at least 72 hours (3 days) to solidify before proceeding to the next step of installation.

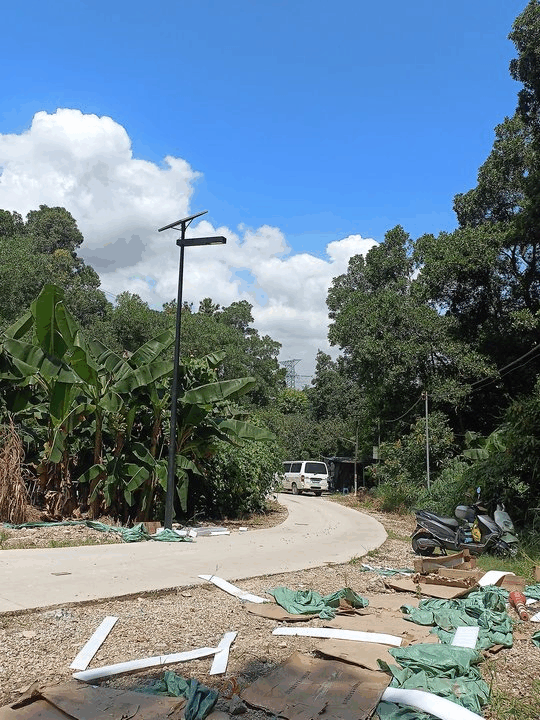

Phase 3: Luminaire Assembly and Hoisting (1-2 days)

Component Assembly: During the curing period, workers assembled the lamp head, solar panel, battery, and other components onto the light pole, connected all wiring, and conducted preliminary tests to ensure proper function.

Hoisting and Fixing: Use a crane to erect the assembled light pole. Align the flange at the bottom of the pole with the pre-embedded bolts in the foundation and securely secure with nuts. Ensure personnel and equipment safety throughout the process.

Angle Adjustment: Adjust the angle of the solar panel to face due south and adjust the optimal tilt angle (usually 15°-45°) based on the local latitude to maximize sunlight reception.

Phase 4: Commissioning and Acceptance (1 day)

Final Test:

Block the light control probe to simulate a dark night environment and verify that the streetlights illuminate properly.

Test the operation of intelligent control functions (such as timed power reduction and sensor functions).

Inspect the lighting performance of all streetlights for dark areas or glare.

Site Cleanup: Clean up construction debris and restore the road surface to its original appearance.

Training Delivery: Explain daily usage precautions and simple troubleshooting methods to the village committee leader (e.g., ensuring the solar panels are unobstructed and clearing snow in winter).

Completion Acceptance: Both parties conduct a joint inspection and sign the acceptance report.

IV. Project Achievements and Benefit Analysis

Lighting Effect: A total of 85 Solway solar streetlights were installed, achieving 100% coverage of the village's main roads and lanes. The average nighttime illumination reached 20-30 lux, with excellent uniformity, resulting in extremely high villager satisfaction.

Economic Benefits:

Zero Electricity Cost: Compared to conventional streetlights, this saves the village tens of thousands of yuan in electricity and maintenance costs annually.

Zero Cable Cost: This eliminates the high costs of laying cables and trenching.

Social and Environmental Benefits:

Safety: Significantly reduced nighttime traffic accidents and public security risks.

Enriched Life: Villagers now have a place to enjoy square dancing, strolling, and chatting at night, enhancing their sense of well-being.

Green and Low-Carbon: The project significantly reduces carbon emissions annually, serving as a model for "Beautiful Village" development.

Maintenance: Over a year after installation, the streetlights have operated reliably, requiring virtually no maintenance, with only one cleaning of the solar panels due to extreme weather (severe sandstorms).

V. Case Summary

The successful implementation of Solway solar street lights in this rural project fully demonstrates its core advantages: reliable product quality, easy installation, energy conservation and environmental protection, and intelligent and efficient design. Its integrated design greatly simplifies the construction process, reducing both difficulty and cost, making it particularly suitable for rural areas where professional electricians are scarce. This project has become a model project emulated and emulated by surrounding townships, proving that solar street lights are one of the best solutions for rural lighting problems.

Note: The above case study is a general description. In actual projects, the specific product model, configuration, spacing, and installation time must be customized based on local latitude and longitude, climate conditions, road conditions, and budget. If you have specific project requirements, we recommend contacting Solway or its authorized dealers directly for a precise solution and quote.

English

English

Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Consult Now

Consult Now